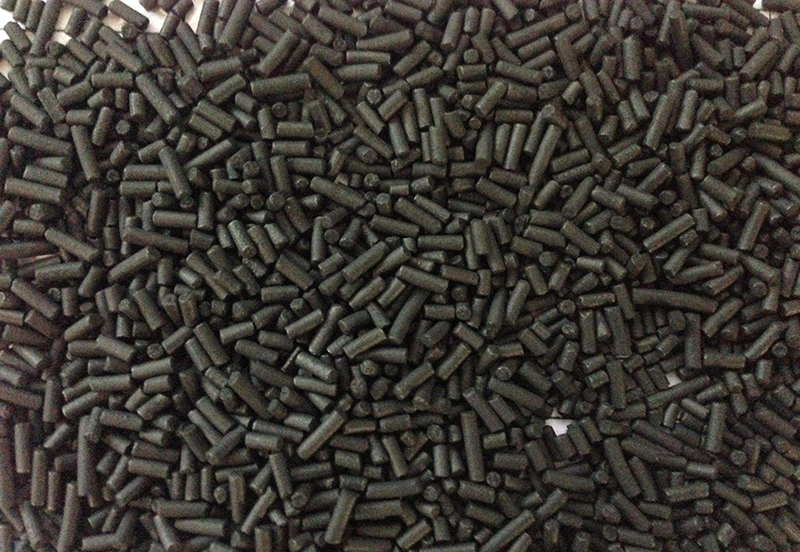

The KM INDUSTRIAL is a carbon molecular sieve enterprise based on HAIHUA technology and production. It’s located in the beautiful Hangzhou.

Haihua Chemical it is a professional manufacturer of carbon molecular sieve for p.s.a pressure swing adsorption nitrogen production. The company's existing production scale ranks first in the same industry.

The carbon molecular sieve series products produced by the company have been successfully used in P·S·A nitrogen production equipment, and have been designated as supporting products by many large and medium-sized pressure swing adsorption manufacturers, and are widely praised by customers at home and abroad.